Polyurethane Materials

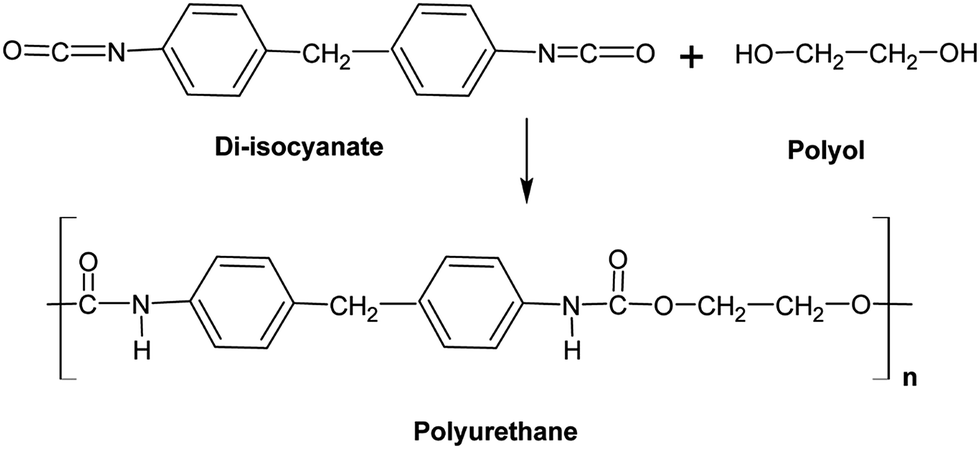

Polyurethane Materials: Polyurethane is a polymer compound, which is polymerized by multiple isocyanate groups and polyol groups. and is known as the “fifth largest plastic”.

Polyurethane Materials Properties

polyurethane is a highly versatile polymer that has many useful properties, including:

good abrasion resistance

high load-bearing capacity

high tear strength

excellent flexibility

resilience

good chemical resistance

low water absorption

good dimensional stability

good electrical insulation

Polyurethane Materials Applications

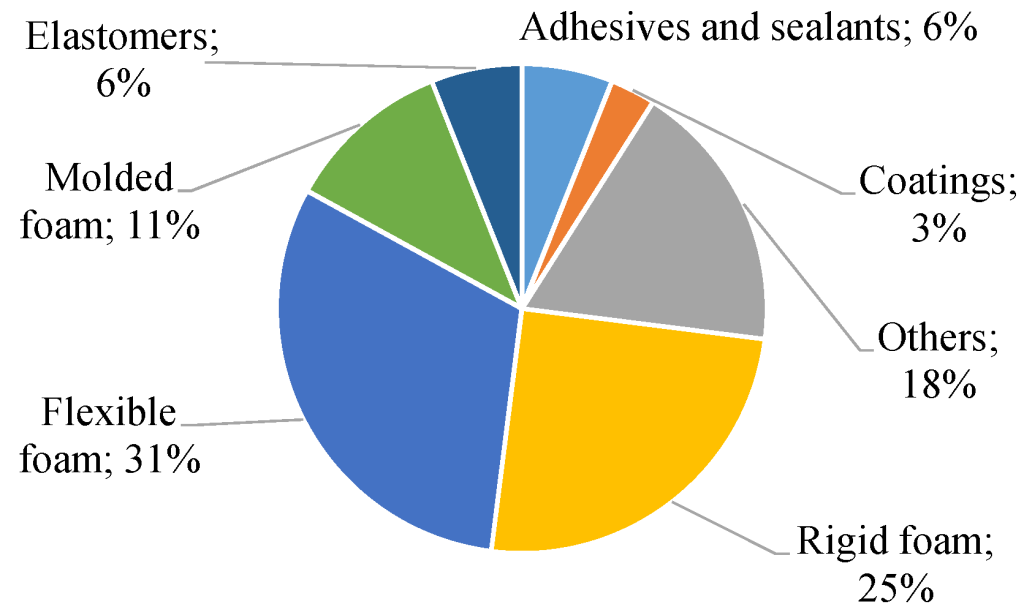

polyurethane has many applications in various industries. some of the most common applications include:

insulation: polyurethane foam is commonly used for thermal insulation in buildings and appliances.

cushioning: polyurethane foam is also used for cushioning in furniture, mattresses, and automotive parts.

coatings: polyurethane coatings are used to protect surfaces from wear and tear, abrasion, and weathering.

adhesives: polyurethane adhesives are used in construction and manufacturing applications where strong bonding is required.

seals and gaskets: polyurethane seals and gaskets are used in a variety of applications, including hvac systems, automobile engines, and hydraulic systems.

wheels and rollers: polyurethane wheels and rollers are used in material handling equipment, printing presses, and other industrial machinery.

overall, polyurethane is a highly versatile material with many useful properties that make it suitable for a wide range of applications.

The properties of polyurethanes can be tuned by choosing different raw materials and processing conditions, making them suitable for various applications.

Such as seat armrests, sealing rings, car cushions, office cushions, neck pillows, mattresses, pillows, lumbar support pillows, cushions, tooth pads, sports protective gear, sealants, rubber rollers, rubber wheels, children’s toy balls, decompression Stress relief toys, polyurethane insoles, simulated bread and food, etc. Applied in home furnishing, automobiles, baby products, medical equipment, sporting goods, toys, food models, animation weapon props, building materials and other products.

Generally, polyurethane products are divided into two types, one is non-foaming products and the other is foaming products.

The foamed product is to mix and stir the raw materials of the two components of A and B through a polyurethane foam machine, and then mix and spray in the mixing chamber. After spraying, it usually starts to foam within 3-5 seconds to form a product.

Non-foaming products are generally mixed with two components of polyurethane raw materials by a polyurethane pouring machine in the mixing chamber of the equipment, and then the raw materials are sprayed out and molded in the mold.

According to the rebound speed, polyurethane can be divided into fast rebound and slow rebound.

fast rebound polyurethane and slow rebound polyurethane are two variations of a synthetic polymer material commonly used in manufacturing various products such as foam pads, cushions, mattresses, and shock absorbers. the primary difference between the two lies in their rebound properties.

fast rebound polyurethane has a higher resilience or elasticity, which means that it can return to its original shape faster after being compressed. this makes it ideal for use in products that require quick recovery time, such as sports equipment or shoe soles. fast rebound polyurethane also offers excellent energy absorption, making it an effective shock absorber.

slow rebound polyurethane, on the other hand, has lower resilience or elasticity, and therefore it takes longer to return to its original shape after being compressed. this makes it suitable for products that require a more cushioned effect or pressure relief, such as pillows or medical devices. additionally, slow rebound polyurethane provides better compression set resistance, which means it maintains its shape even after prolonged use and repeated compressions.

fast rebound polyurethane is best suited for applications where quick recovery time and energy absorption are essential, while slow rebound polyurethane is more appropriate for products requiring more gradual and long-lasting cushioning effects.

Polyurethane Type

polyurethane is a versatile polymer that has different types, each with unique properties and applications. here are some of the various kinds of polyurethane:

flexible polyurethane foam – commonly used in cushioning applications for furniture, automotive, bedding, and insulation.

rigid polyurethane foam – used as structural or insulating material for refrigeration, construction, and packaging industries.

coatings and adhesives – polyurethane coatings offer excellent resistance to chemicals, abrasion, weathering, and uv radiation, making them ideal for protective film applications. polyurethane adhesives offer high strength bonding, flexibility, and a variety of curing mechanisms.

thermoplastic polyurethane (tpu) – a type of elastomer that combines the properties of rubber and plastics, used in medical.

One of the most obvious advantages of polyurethane Materials is its versatility. It is a material that, by varying the formulation of the components, can take on very different physical characteristics, allowing in any case a freedom to design the products almost without limits.

The above is the explanation about polyurethane materials, I hope it will be helpful to everyone.