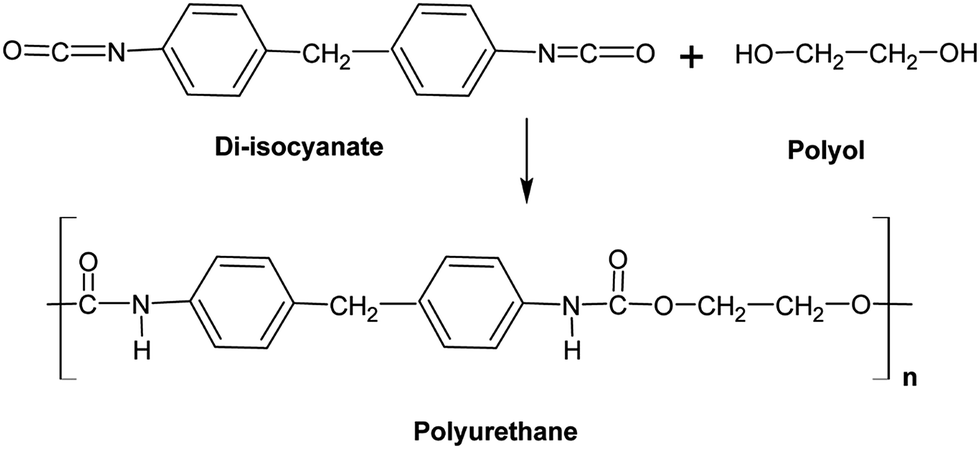

Polyurethane is a polymer compound, which is polymerized by multiple isocyanate groups and polyol groups. It has excellent mechanical properties, wear resistance, corrosion resistance, chemical resistance, insulation and various physical and chemical properties. Polyurethanes are commonly used to make foams, coatings, adhesives, elastomers, plastics, fibers and other industrial and consumer products. The properties of polyurethanes can be tuned by choosing different raw materials and processing conditions, making them suitable for various applications.

Polyurethane Foam Products

Polyurethane foaming is to mix polyurethane raw materials through special equipment, then react under certain temperature and pressure conditions to generate gas, and expand into foam materials with certain density and strength in a short time. Due to its good insulation performance, heat dissipation performance, sound absorption performance and other characteristics, it is widely used in construction, automobiles, home appliances, toys, medical equipment, aerospace and other fields.

Advantages of Polyurethane

Polyurethane is a multifunctional polymer material with the following advantages:

Good processability:

Polyurethane can be shaped by various processing methods, such as injection molding, extrusion, calendering, etc.

Excellent physical and mechanical properties: Polyurethane has relatively high strength, wear resistance and elasticity, and maintains good flexibility in low temperature environments.

High Strength to Weight: Polyurethane has a lower density, allowing it to weigh less than other materials while maintaining high strength.

Good chemical resistance: Polyurethane has good corrosion resistance to various chemical substances, and has good resistance to acids and alkalis, oils and solvents.

Good thermal insulation performance: Polyurethane foam has good thermal insulation performance, so it is widely used in the field of building insulation.

Good waterproof and moisture-proof performance: polyurethane foam has good airtight performance and will not lose its performance due to the influence of humidity.

Polyurethane has many excellent properties, so it is widely used in construction, transportation, home appliances, toys, medical equipment, aerospace and other fields.

What products can be made of polyurethane

Polyurethane can be made into many different products, here are some specific examples:

Foam insulation: Polyurethane foam is an excellent insulation material that can be used in construction, electrical appliances, and refrigeration equipment.

Elastomer: Polyurethane elastomer has excellent elasticity and durability, and is often used in fields such as car seats, furniture cushions and shoe soles.

Coatings and Adhesives: Polyurethane coatings can be used to finish surfaces such as wood, metal and plastic, while polyurethane adhesives can be used to bond various materials.

Cellulose material: Polyurethane fiber can be made into nylon fabric, elastic fabric and sponge material.

Polyurethane sheets: Polyurethane sheets are made of compressed polyurethane foam and are used for insulation of walls, roofs and floors.

In short, polyurethane has a wide range of application fields and rich product forms.

One of the most obvious advantages of polyurethane is its versatility. By changing the formulation of the ingredients, the material can exhibit vastly different physical properties, allowing almost unlimited freedom to design the product in any case.

Polyurethane Foam Toys

Polyurethane is a polymer material with excellent physical and chemical properties and can be used to make various toy products. Here are some of the toy products that polyurethane can be made from:

Stuffed toys: Polyurethane foam has low density, softness and good elasticity, and can be used to make stuffed toys, such as dolls and mats.

Elastic toys: Polyurethane materials have good elasticity and recovery, and can be used to make elastic toys, such as bouncing balls and plasticine.

Model toys: Polyurethane materials have excellent molding properties, and can produce model toys of various shapes and sizes, such as airplanes, cars, and ships.

Simulation toys: Polyurethane can adjust properties such as color and hardness according to different needs, and can be used to make simulation toys, such as fruits and vegetables.

In short, polyurethane materials can be applied to make various toy products, which are characterized by safety, environmental protection, durability and easy processing.

Flexible Polyurethane Products

Flexible polyurethane is an elastomeric material commonly used to make cushioning materials, mattresses, cushions, etc. Here are some common flexible polyurethane products:

Mattresses: Flexible polyurethane mattresses are the sleep mattress of choice for many due to their comfort and support properties.

Cushions: Flexible polyurethane cushions can provide extra support and comfort and are often used in office chairs, car seats.

Cushioning material: Flexible polyurethane has a wide range of applications in both industry and sports, such as racket handles, insoles, and bicycle seats.

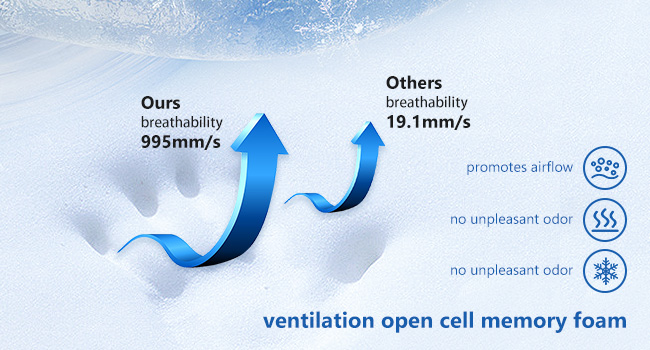

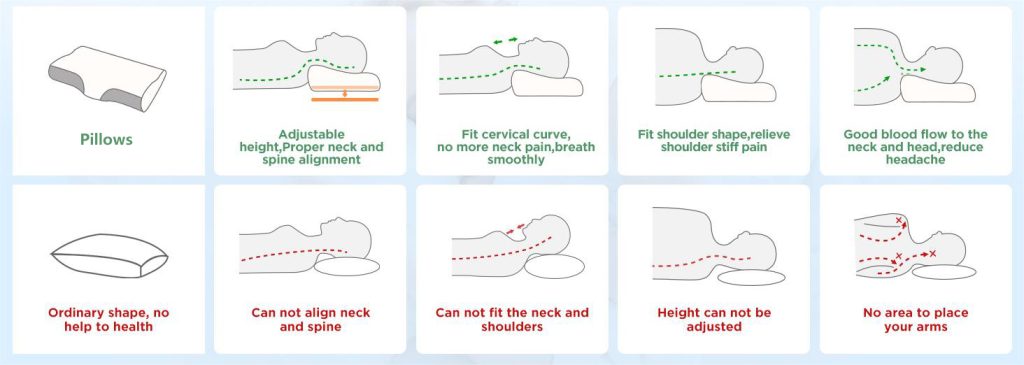

Cushions and pillows: The flexible polyurethane material can be made into cushions and pillows of various shapes and sizes for extra support and comfort.

Car interior decorations: flexible polyurethane can be made into decorations such as car seats, steering wheel covers, safety armrests, etc., providing extra comfort and anti-slip functions.

Flexible polyurethane is a highly functional material that can be used in a variety of comfort and support products.

Rigid Polyurethane Products

Rigid polyurethane is a high-performance polymer material commonly used in the manufacture of a wide range of wear, corrosion and chemical resistant products. The following are several application products of rigid polyurethane:

Foamed polyurethane board: Foamed polyurethane board is a lightweight, high-strength, and good thermal insulation building material. It is widely used in thermal insulation of building roofs, walls, floors and other parts.

Polyurethane coatings and adhesives: Polyurethane coatings and adhesives are widely used in construction, automotive, aerospace and other fields. These products have excellent wear resistance, corrosion resistance and adhesive properties, and can effectively protect and repair different types of surfaces.

Polyurethane elastomer: Polyurethane elastomer is a material with high elasticity and high toughness, which is widely used in vibration and noise control, sealing and cushioning in the fields of automobiles, railways, electric power, construction, etc.

Polyurethane foam: Polyurethane foam is a light-weight material with good heat insulation performance, which is widely used in the manufacture of refrigerators, air conditioners, thermos cups and other products.

Polyurethane molded parts: Polyurethane molded parts have excellent processability and physical properties, and are widely used in the manufacture of automobiles, home appliances, industrial equipment and other fields.

Integral Skin Polyurethane Foam

Good wear resistance: Polyurethane self-soiling skin has excellent wear resistance, and can be used for a long time in various environments without abrasion.

High strength: Due to the tight molecular chain structure of polyurethane self-skinning, it has high strength and rigidity and can withstand high loads.

Corrosion resistance: Polyurethane self-skinning can withstand the erosion of various chemical substances, and can be used in harsh environments such as acids, alkalis, and solvents.

Good water resistance: The surface of polyurethane self-skinning is very smooth, which can effectively prevent moisture from penetrating, making it suitable for use in humid environments.

Integral skin foam offers a more high-density and thicker dense outer skin. However, the underlying foam core is lower density. The hardness of the material can vary depending upon formulation, density and product application.

Integral skin that offers a thicker outer skin which is ideal for a number of applications including arm rests.

Polyurethane Foam Products Manufacturer

Dongguan Shengmei Plastic Products Co., Ltd. Has a 25+ years of experience in polyurethane foam products technology, we produce highly engineered polyurethane molded products parts for the markets including self-skinning and small pour molded polyurethane components, medical, pillows, cushions, footwear, impact protection, sporting goods and toys.

SMPUFOAM is now the most trusted manufacturer of polyurethane foam products.